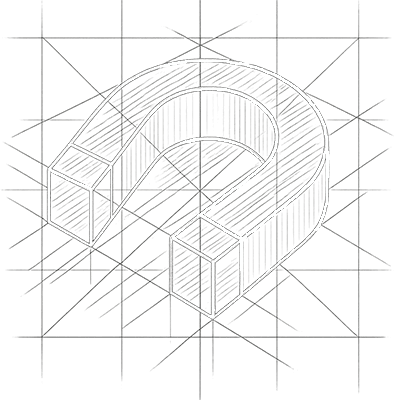

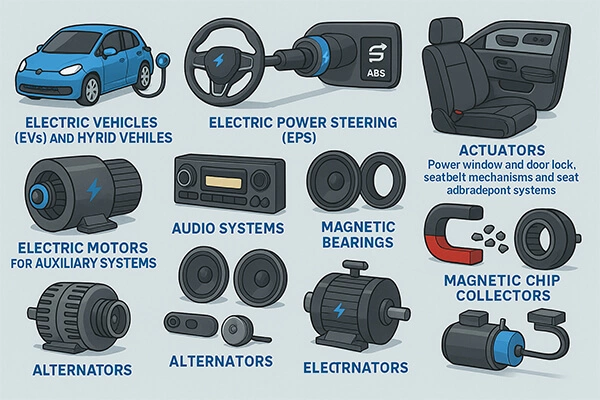

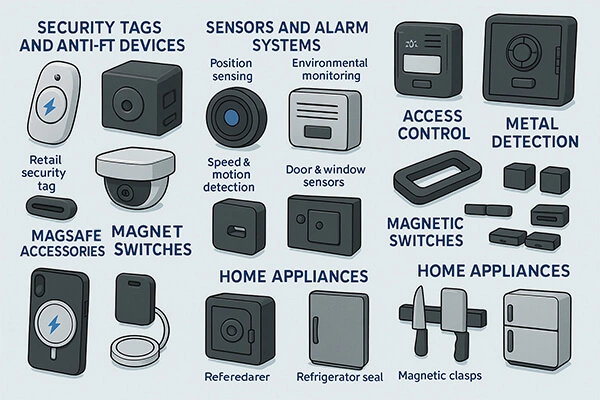

The manufacturing process of neodymium magnets is a highly sophisticated and multi-stage operation that requires precise control of raw materials, processing parameters, and quality assurance measures. Each step in the process plays a critical role in determining the final magnetic properties and performance of the magnets, making them a key component in a wide range of modern technologies.

The neodymium magnet manufacturing process typically involves the following key steps:

(1) Raw Material Preparation

The primary raw materials for neodymium magnets are neodymium (Nd), iron (Fe), boron (B), and small amounts of other elements such as dysprosium (Dy) and praseodymium (Pr) to enhance coercivity and thermal stability. These rare earth magnets' elements are carefully measured and mixed in specific ratios to achieve the desired magnetic properties.

However, the addition of dysprosium can sometimes slightly reduce the maximum energy product (a measure of the magnet's strength), so the optimal composition is a careful balance to meet the specific requirements of the application.

The mixture is then melted in a vacuum induction furnace at extremely high temperatures, typically exceeding 1,400°C (2,552°F). This high-temperature melting process ensures a homogeneous blend of the elements and eliminates any impurities that could degrade the magnet's performance.

(2) Strip Casting

Once the molten alloy is prepared, it is rapidly cooled using a process called strip casting. In this method, the molten metal is poured onto a rotating copper wheel, which rapidly solidifies the alloy into thin strips or ribbons.

The precisely formulated mixture of raw materials is fed into a melting furnace, typically under an inert atmosphere (like argon) to prevent oxidation. This rapid solidification is significantly faster than traditional casting methods.

This rapid cooling rate is crucial as it helps to form a fine, uniform microstructure in the alloy, which is essential for achieving high magnetic properties. The resulting strips are typically a few tens of micrometers thick and have a width of several millimeters.

(3) Hydrogen Decrepitation (HD)

The strip-cast alloy is then subjected to hydrogen decrepitation, a process that involves exposing the material to hydrogen gas at elevated temperatures. Hydrogen atoms diffuse into the alloy, causing it to fracture into fine powders.

The process typically begins by loading the cast alloy strips into a reaction vessel. This vessel is then evacuated to remove air and other impurities before being filled with hydrogen gas at a controlled pressure, usually at a moderate temperature ranging from 80 to 200 degrees Celsius.

This step is important as it reduces the particle size of the alloy, making it easier to align the magnetic domains during subsequent processing steps. The HD process also helps to remove any remaining impurities and improves the homogeneity of the powder.

(4) Jet Milling

Following hydrogen decrepitation, the powder is further refined using jet milling. In this process, the powder is accelerated through a high-velocity gas stream and collides with a target or other powder particles, resulting in further size reduction.

The jet milling process operates on the principle of attrition and impact. The coarse powder from the HD process is fed into a specially designed milling chamber. Within this chamber, high-speed jets of compressed gas, typically an inert gas like nitrogen or argon to prevent oxidation of the highly reactive neodymium powder, are directed at the powder particles.

Jet milling produces fine, spherical particles with a narrow particle size distribution, typically in the range of 3-5 micrometers. The uniform particle size and shape are critical for achieving high magnetic properties and good sinterability.

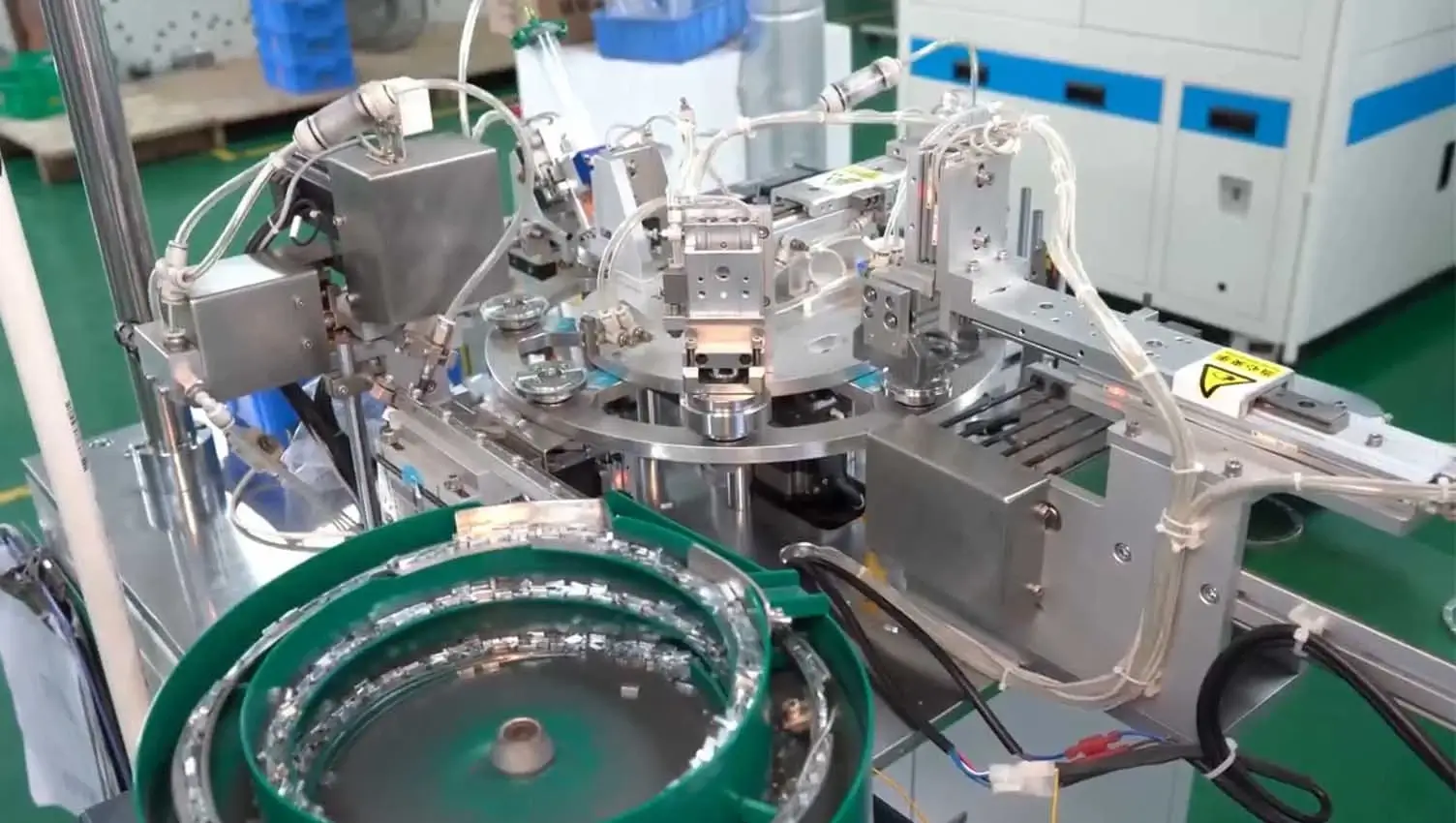

(5) Magnetic Alignment and Pressing

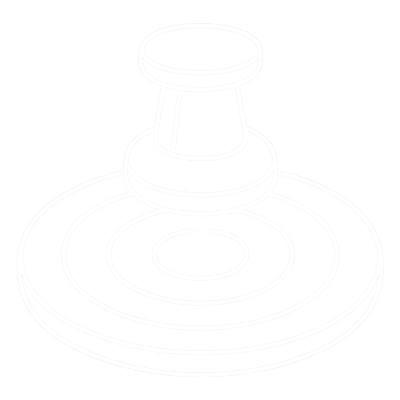

The fine powder is then mixed with a small amount of binder or lubricant to improve its flowability and facilitate pressing. The powder is placed in a magnetic field and pressed into the desired shape using a die-pressing or isostatic pressing method.

The pressing is typically done using mechanical or isostatic pressing techniques. In mechanical pressing, pressure is applied uniaxially (in one direction) by punches moving within the die. The high pressure forces the powder particles into close contact, increasing the density and providing sufficient mechanical strength for the subsequent sintering process.

The magnetic field aligns the magnetic domains within the powder particles, ensuring that the resulting magnet has a preferred magnetization direction. This alignment process is crucial for maximizing the magnet's remanence (Br) and energy product ((BH)max).

(6) Sintering

The pressed green bodies are then sintered in a vacuum or inert gas atmosphere at high temperatures, typically between 1,000°C and 1,100°C (1,832°F and 2,012°F). During sintering, the powder particles bond together through diffusion, forming a dense, solid magnet.

A higher density reduces the presence of non-magnetic voids, allowing for a greater volume of magnetically aligned material, thus enhancing the overall magnetic flux density.

The sintering process also helps to eliminate any remaining pores or voids within the magnet, improving its mechanical strength and magnetic properties. After sintering, the magnets are slowly cooled to room temperature to prevent thermal cracking.

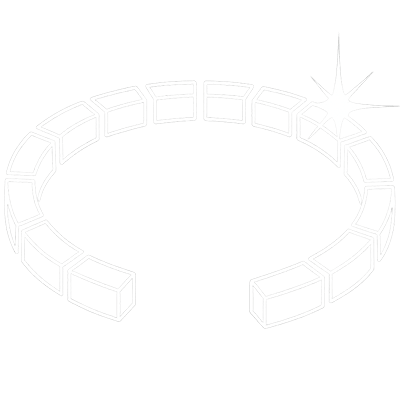

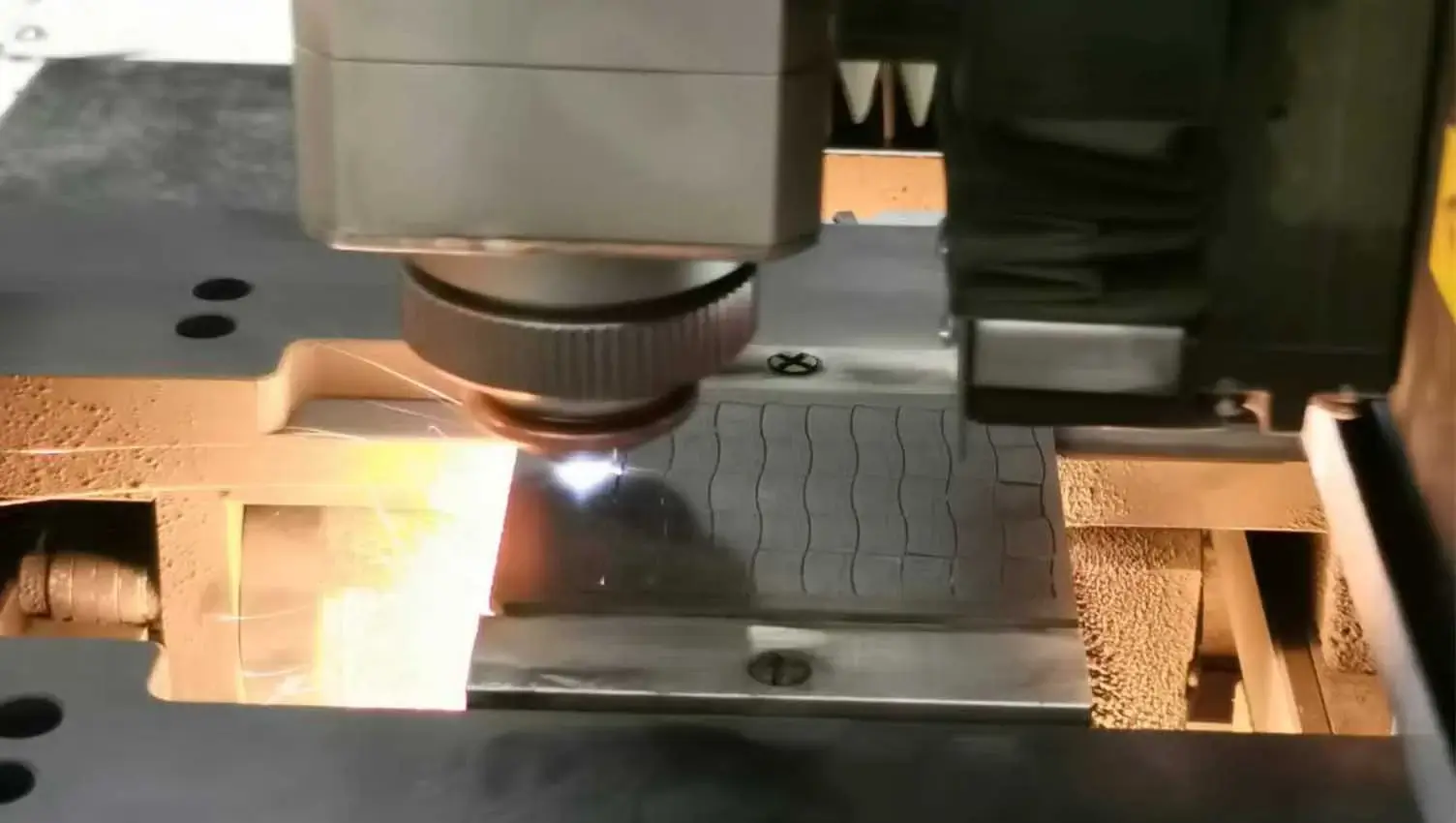

(7) Machining and Surface Treatment

Once sintered, the magnets may require further machining to achieve the final dimensions and tolerances. Common machining processes include grinding, slicing, and drilling. To protect the magnets from corrosion and improve their durability, they are often coated with a thin layer of nickel, zinc, or epoxy.

The most common type of coating for neodymium magnets is a multi-layer nickel-copper-nickel plating. Careful control of the plating parameters, such as bath composition, temperature, and current density, is essential to ensure a uniform and adherent coating.

Surface treatment also enhances the magnets' appearance and can provide additional benefits such as improved adhesion for subsequent assembly processes.

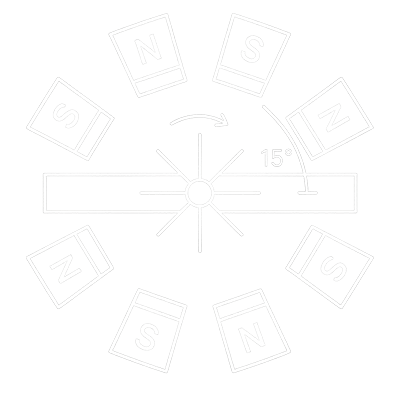

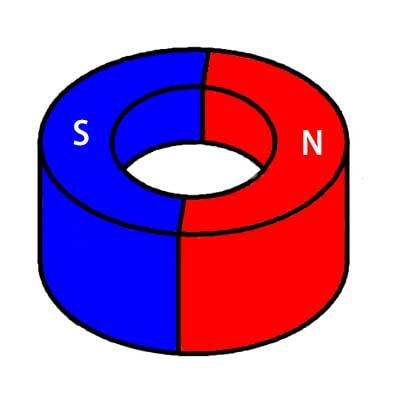

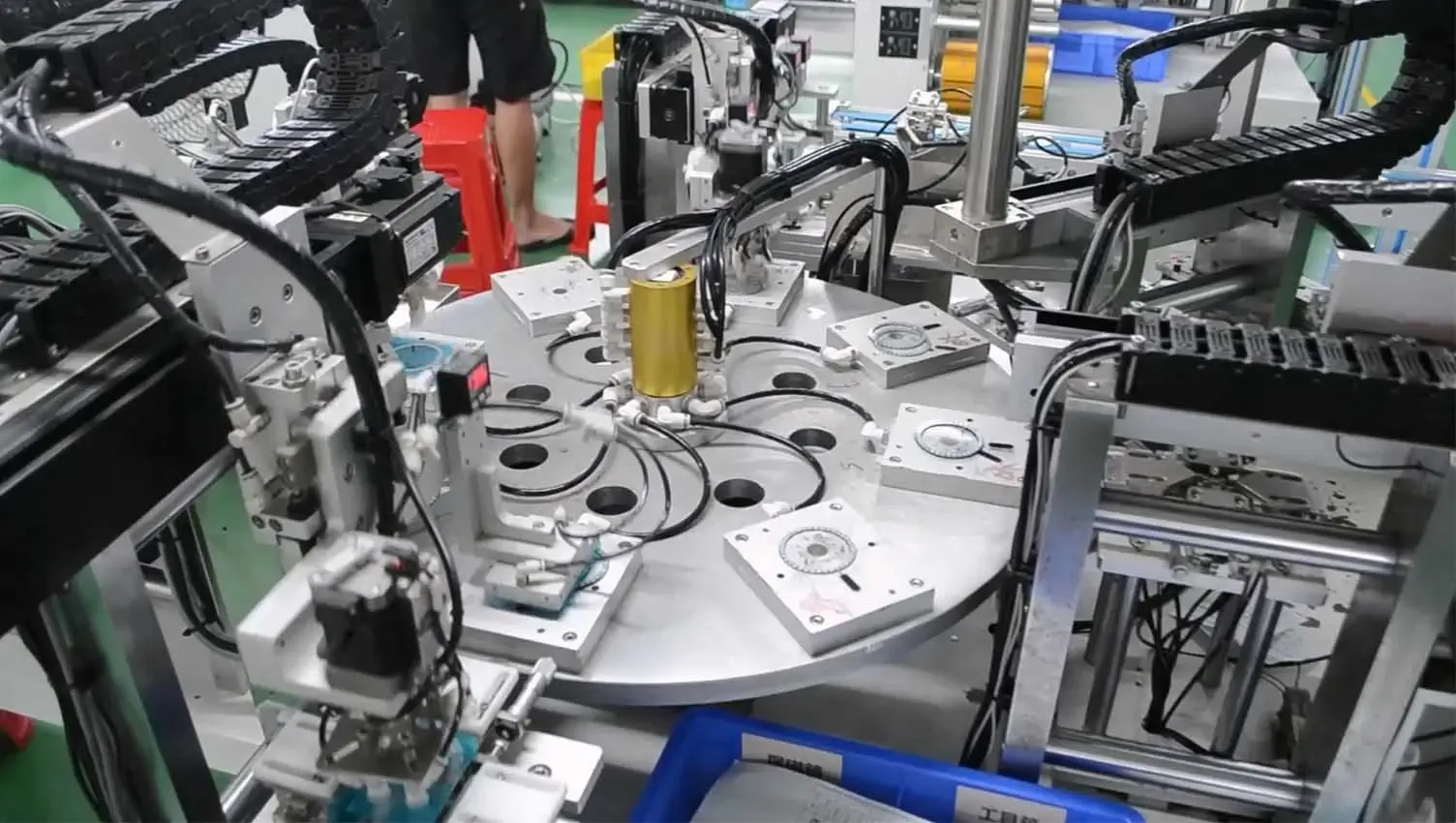

(8) Magnetization and Quality Control

The final step in the manufacturing process is magnetization, which is the simplest process among all above. The magnets are placed in a strong magnetic field for strong magnets, typically generated by an electromagnet in pulse magnetizer, to align their magnetic domains and achieve their full magnetic potential.

After magnetization, the magnets undergo rigorous quality control testing to ensure they meet the specified magnetic properties, dimensional accuracy, and surface finish requirements. This may include measurements of remanence, coercivity, energy product, and magnetic field strength using specialized equipment such as a hysteresis graph or fluxmeter.

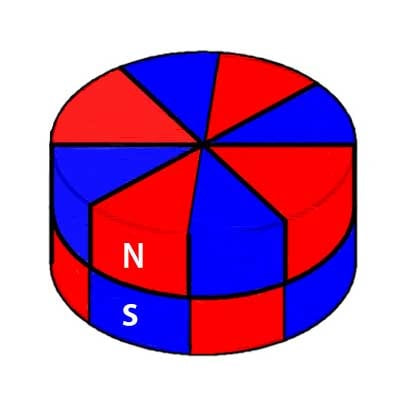

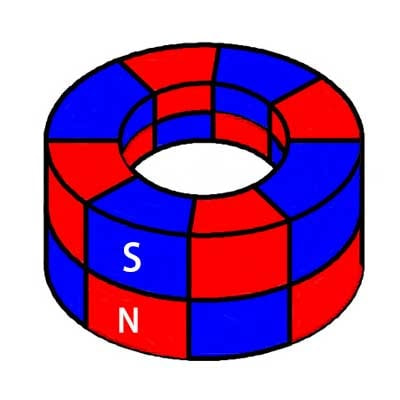

For magnets with specific pole configurations, specialized magnetizing fixtures are used to apply the field in the desired pattern. Any additional tests might be performed to assess their performance under specific environmental conditions, such as temperature stability and resistance to demagnetization.

Comprehensive documentation and traceability are maintained throughout the entire manufacturing process, allowing us to track the history and quality of each magnet. Our commitment to stringent quality control at every stage ensures that the neodymium magnets leaving our facility in Dongguan are of the highest quality and will perform reliably in their intended applications.